Sales Department: 0086-532-87605018

After-sale Service: 0086-532-87660287

E-mail: export_sales@haitongyuanda.com

Roller Oven is a special equipment for heating and aging drilling fluid.

The whole structure of this product has been improved on the basis of the original roller oven to have more reasonable design. The bottom of the box has been reinforced, and there is a roller support plate in the box, firmly located on the bottom plate of the box and make the roller run more smoothly. The insulation layer thickness of the whole box body reaches 80mm to have better insulation performance. The heating rod is placed on the upper side of the box body, and under the action of the top cooling fan, the whole box body is heated more evenly. The insulation layer on the back side of the box can be directly disassembled, and the maintenance is more convenient and quick.

This product adopts the advanced PID intelligent control technology with direct setting and digital display. Electrical configuration is more reasonable, safe and accurate. The motor is equipped with a speed regulating device, which can adjust the running speed of the drum. All switch buttons are additionally provided with indicator lights for more intuitive and clear operation. Circuit safety devices are enabled, which provides a safer operating environment for testers.

Product advantages: smoothly run, low noise, high precision, wide working range, high degree of automation, simple operation, firmness and durability, and convenient maintenance. It can provide more accurate test results for aging test at high temperature.

R&D background of product: In view of the problems of uneven heating, substandard temperature and inconvenient maintenance of roller oven in the market, we developed this product.

The development of this project started on March 15th, 2019, mainly including structural design, manufacturing, circuit design and assembly, etc. After complete the production, the tests are carried out to verify its feasibility.

I. Problems encountered in the process of structural design:

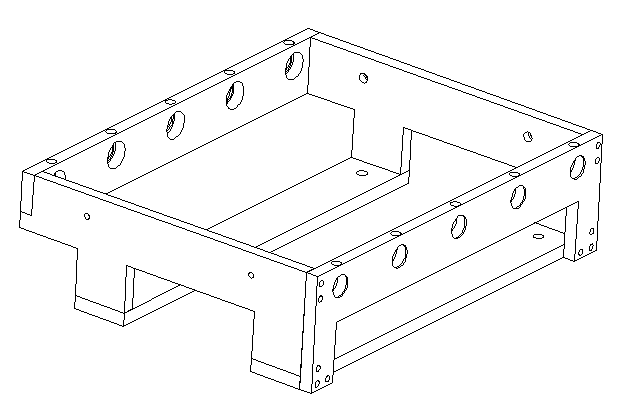

(1) In order to make the bottom of the box more stable, we improve its structure on the basis of the original roller support plate, see below picture. In this way, it can be firmly located on the bottom plate of the box body and make the roller more stable in the running process

(2) How thick is the insulation layer of the whole box body? After calculate the data, we determine to thicken the insulation layer to 80mm, which can make the insulation performance better.

(3) In order to solve the problem of uneven heating temperature in the oven, we thought out many methods, such as the installation position and mode of heating rod, etc. Finally, the heating rod is placed on the upper side of the box body, a cooling fan is installed on its top, and a fan guide device is installed around the fan, which can make the heating inside the whole box body more even.

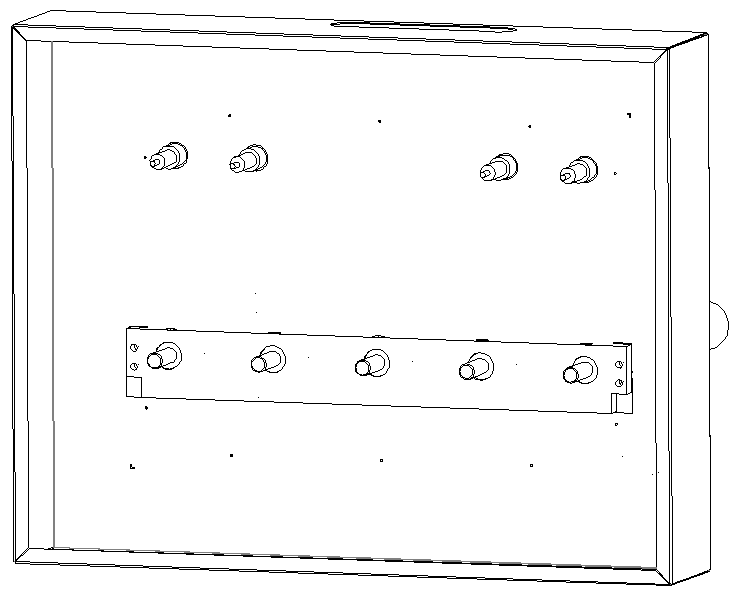

(4) In view of the problem of convenient maintenance, the following scheme was finally put forward, that is, the back side plate of the box body can be disassembled after disassembling the back support plate to have more convenient and faster maintenance. See below picture.

I. The problems encountered in the design of control system:

Upgrade the existing control technology, and finally adopt the latest PID intelligent control technology under the conditions of safety, intuition and precision, with direct setting and digital display. The motor is equipped with speed regulating device, which can adjust the roller running speed. All switch buttons are added with indicator lights to makes the operation more intuitive and clear; Circuit safety devices are enabled to provide a safer operating environment for testers.

III. Problems encountered during the test:

During the test, the rotating speed of the cooling fan is too fast, so we consider add a speed regulating device to the circuit control system.

After we finished the final product, the ultra-high temperature pressure-bearing kettle is put into the ultra-high temperature roller heating oven for test, and the test is successful.